The working principle of the self-priming pump is to fill the pump casing with water (or water in the pump body) before it can be started. After starting, the impeller rotates at high speed to make the water in the impeller channel flow to the volute. The air inlet forms a vacuum, so that the air inlet check valve opens, and the air in the suction pipe enters the high-lift self-priming pump and reaches the outer edge through the impeller channel.

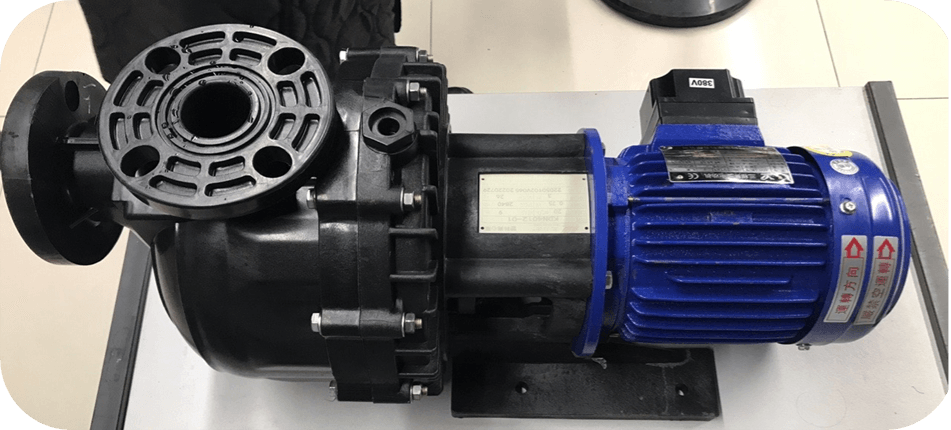

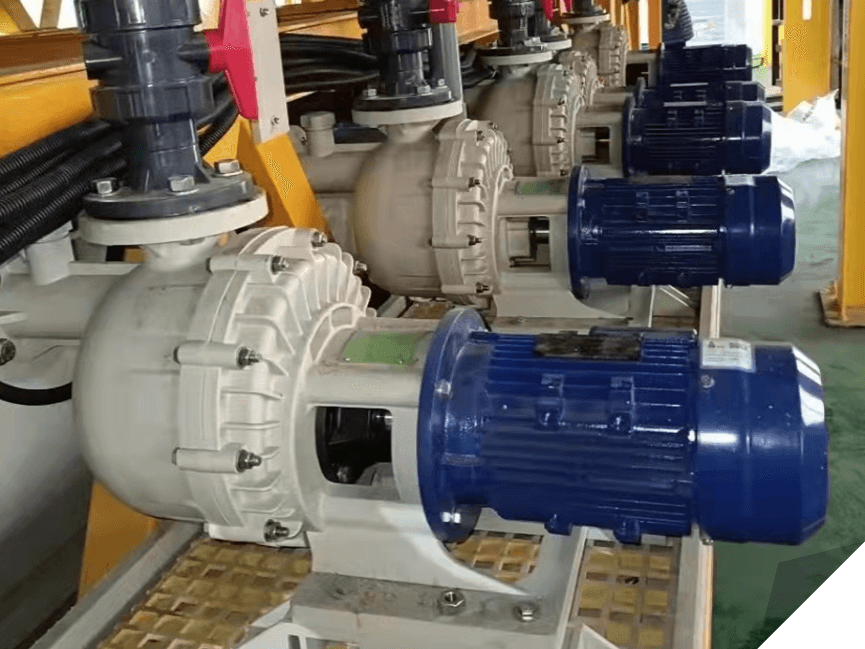

Self-priming centrifugal pump is a kind of machinery that can continuously and uninterruptedly transport liquid, which is widely used in various fields such as industry, agriculture, urban water supply and drainage. When the air in the pump suction line is exhausted and the gas is discharged from the outlet, it mixes with the liquid in the pump suction chamber to form a circulating flow. The internal structure of the self-priming centrifugal pump is mainly composed of pump body, impeller, guide vane, motor and other parts. After turning, it enters the middle of the pump body for continuous circulation.

Advantage one: strong suction

The self-priming pump uses the physical characteristics of air pressure in the working principle to make the air automatically form a reverse suction cycle state, so that it can better absorb dust and dirt in the water and make the environment cleaner. The self-priming pump uses its own pressure to clean up most of the impurities and sundries in the pool, which makes users more flexible and convenient during use.

Advantage two: easy to operate

The use of the self-priming pump is very simple. Generally, the operation can be completed independently through the operation and processing of the pressure link. On the top of the self-priming pump, there will be three gear buttons of high, medium and low as the basis. During the initial start-up period, because the self-priming pump has not fully adapted to the current working state, the way of advancing from the low gear to the high gear, It can ensure better inhalation effect.

Post time: Dec-07-2022